Your Customized Plastis Injection Molding Manufacturer In China

Elevate your project from concept to reality with Rich Mold, experience the seamless transformation of your designs into high-quality plastic parts

Meet the Right Services

Our Manufacturing Services

Rapid Molding

Get parts in weeks, not months. Rapid molding delivers low-volume, high-precision parts quickly, perfect for testing, market validation, or short-run production. With fast turnaround times, You can iterate and refine designs without delays—because in your market, speed matters. Let’s keep you ahead of the curve!

Insert Molding

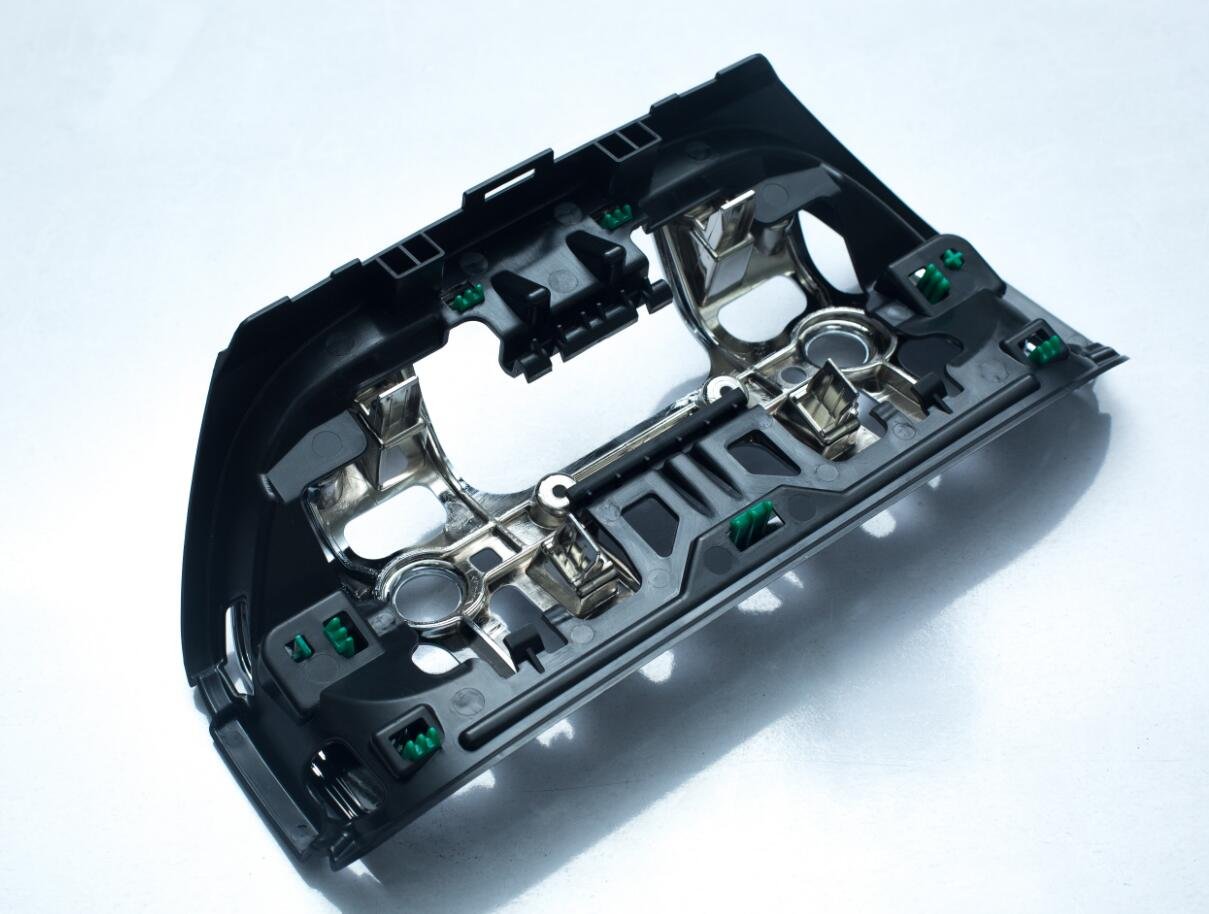

Boost your product’s strength with insert molding. This method integrates metals or other materials directly into plastic, creating durable, multi-material components in one shot. Say goodbye to extra assembly—you get enhanced durability and reduced production steps, perfect for complex, high-performance parts.

2K Molding

Achieve complexity with 2K injection molding, seamlessly combining two materials in a single mold cycle. Perfect for multi-functional parts or dual-color designs, it saves time and boosts product strength. you get more design flexibility, fewer assembly steps, and a product that stands out.

Family Molding

Family molding produces multiple parts with different shapes in one mold, reducing production time and costs. It’s ideal when you need various components molded together. Streamline your supply chain, save on tooling costs, and get consistent quality across all parts in a single run.

Overmolding

Overmolding fuses different materials into one cohesive part, like a soft-touch layer over a rigid base. This process enhances grip, durability, and shock resistance. you get an ergonomic and visually appealing product, perfect for high-value consumer goods, electronics, and medical devices.

Reaction Injection Molding

Reaction injection molding (RIM) combines two liquid polymers that react inside the mold to form lightweight yet durable parts. Ideal for producing large, complex shapes, you get a versatile solution for automotive, medical, and industrial applications with reduced weight and enhanced strength.

Company Information

Precision Manufacturing, Customized Solutions

At Rich Mold, we excel in custom plastic injection molding, turning complex concepts into precision-crafted components. Our state-of-the-art facility is designed for flexibility, handling everything from prototypes to large production runs. With a focus on quality, speed, and tailored solutions, Rich Mold ensures your innovative ideas reach the market efficiently and flawlessly.

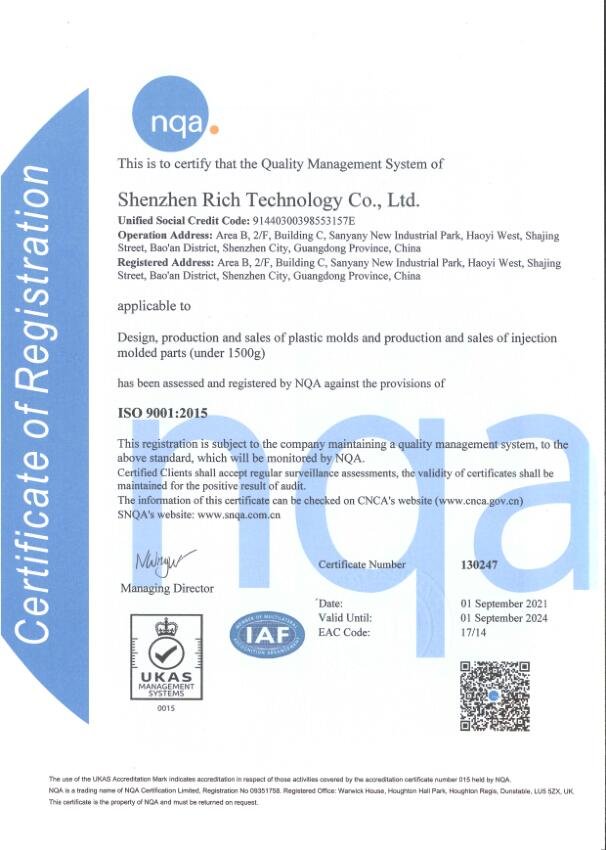

ISO9001

ISO14001

IATF16949

ISO13485

-scaled.jpg)

Technical Support

Design and Engineering Support

At Rich Mold, your vision takes shape with advanced CAD tools and 3D modeling. Our Design for Manufacturing (DFM) approach optimizes every detail, ensuring smooth, cost-effective production. From concept to prototype, you get precise, practical designs, ready for market success—efficiently engineered to meet your exact needs.

Most Important

Quality Assurance

-1-1024x683.jpg)

Industries Catered

Rich Mold serves diverse industries with precision injection molding solutions. From automotive to consumer electronics, our custom-engineered components meet strict standards across medical, industrial, and energy sectors, delivering reliability, efficiency, and quality at every scale.

Auto

Rich Mold powers your automotive projects with precision injection-molded parts, from lightweight housings to intricate gears and trim components. Our capabilities ensure tight tolerances, heat resistance, and durability, meeting the industry’s toughest safety standards.

You get optimized, cost-effective solutions for both electric and conventional vehicles, driving quality and efficiency into every mile.

Medical

Precision and reliability are essential in medical device manufacturing. Rich Mold specializes in producing biocompatible, high-precision components for medical devices, surgical instruments, and implantable parts. Our ISO 13485-certified processes ensure compliance with strict industry standards.

We offering custom solutions that meet the unique needs of medical applications, from prototypes to full-scale production.

Aerospace

Rich Mold’s injection molding solutions power the aerospace industry with lightweight, high-strength components that meet the toughest standards. From intricate interior fittings to robust structural elements.

You get precision-molded parts that excel in durability and reduce weight, ensuring your aircraft components perform flawlessly under extreme conditions.

Electronics

Our injection molding solutions are built for consumer electronics. Whether it’s sleek enclosures, durable connectors, or precise internal components, you get parts that offer thermal stability, impact resistance, and impeccable surface finishes.

Tailored for high-demand applications, our solutions ensure every device meets the industry’s toughest standards and user expectations. Let’s power up your tech game!

Agriculture

You need parts that can handle tough environments, and Rich Mold delivers. Our precision-molded(PDCPD Reaction Injection Molding) components for agriculture include durable irrigation systems, weather-resistant greenhouse parts, and robust equipment housings.

Expect performance that lasts, boosting productivity while reducing wear and tear—because you deserve solutions that work as hard as you do.

Sports Equipment

Boost your sports equipment with precision-engineered injection-molded components from Rich Mold. Whether it’s lightweight grips, durable protective gear, or ergonomic handles, you get high-strength, impact-resistant parts tailored to withstand intense use.

Our advanced molding ensures superior performance and comfort, helping you deliver winning products in a competitive market.

Our Testimonials

Real Reviews from Real Customers

In our quest for specific sheet metal and high-gloss plastic parts, Rich Mold was a game-changer. They nailed the infrared transmittance and powder coating we needed. It’s rare to find a supplier who truly gets the nuances of our product needs. Partnering with Rich Mold has been a key factor in the quality and appeal of our heaters.

Dominik

Company Head

For our beauty device handle, finding a supplier who could handle everything from silicone to stainless steel with precision was challenging. Rich Mold delivered beyond expectations – the parts fit perfectly, the plastic is tough enough to withstand drops, and the metal finishes are top-notch. They’ve elevated our product’s quality and durability, making them an invaluable part of our supply chain.

Sara

Company Purchaser

Designing a unique beer tower for Budwei, we needed parts that were not only food-grade and transparent but also viable for mass production without breaking the bank. Rich Mold struck the perfect balance, bringing our design to life while keeping costs in check. Their expertise in material selection and manufacturing has been crucial to our project’s success.

Jonathan

Product Design Engineer

FAQs About Rich Mold 's Services

We’ve compiled the most frequently asked questions about our one stop manufacturing services for your convenience. However, should you have any additional questions, please don’t hesitate to contact us.

At Rich Mold, our one-stop service streamlines your project from start to finish. Enjoy seamless transitions from design for manufacturability (DFM) to prototyping, mold making, and small to medium volume production. This cohesive approach not only saves you time and resources but also ensures consistent quality and communication throughout your project's lifecycle.

We handle in-house tooling design and maintenance, ensuring precise mold performance and longevity, reducing downtime, and improving consistency.

Our team is equipped to support you during the product design stage. We provide valuable insights for DFM, helping you understand various material types and optimizing your design for manufacturability, thereby saving you time and money.

We offer a range of finishes, including high polish, matte, textured, silk screen printing, laser engraving, and painting,ultrosonic welding,plating tailored to your product’s aesthetic and functional needs.

Yes, we provide part assembly services to add value to your production process. This service complements our manufacturing capabilities, ensuring a complete solution from part fabrication to assembly, tailored to your project needs.

Costs depend on factors like material selection, tooling complexity, part design, and order volume. We provide specialized optimization solutions for your project and competitive quotes tailored to your specific needs.

Prompt Notification: We encourage you to notify us as soon as you detect any defects. Our customer service team is always ready to assist you.

Assessment & Verification: Upon receiving your notification, we initiate a quick assessment to verify the issue. This may involve requesting photos of the defect, or in some cases, returning the part for inspection.

Swift Resolution: Based on the assessment, we offer appropriate solutions which could include repairing the defective part, manufacturing a replacement, or in certain circumstances, issuing a credit or refund.

Root Cause Analysis: To prevent future occurrences, we conduct a thorough analysis to identify the root cause of the defect and take corrective actions in our manufacturing processes.

Continuous Support: Throughout the process, our team maintains open communication with you, providing regular updates and ensuring that your concerns are addressed promptly and satisfactorily.

Lead times vary based on project complexity and volume. However, we pride ourselves on efficient processes, typically offering faster turnarounds than industry averages, especially for small to medium-sized orders.

Our payment terms are designed to be client-friendly, usually involving an initial deposit with the balance payable upon project completion. We strive for transparency and flexibility to accommodate your financial planning.

Yes, our advanced high speed plastic injection molding machines and precision tooling allow us to produce complex parts with tight tolerances as +/-0.05mm and intricate designs.

Yes, we offer comprehensive technical support and guidance right from the onset of your project. Our team of experts is ready to assist with any technical queries or challenges, ensuring a smooth start to your project.

Quality is paramount at Rich Mold. We implement rigorous quality control processes at every stage of production, from initial design to final output. Our adherence to ISO 9001 standards is a testament to our dedication to delivering superior quality parts.

We pride ourselves on flexibility, including in our MOQ policies. We accept orders as small as a single prototype and scale up to thousands of units, offering solutions that are tailored to your project's specific needs and scale.

Timely delivery is a cornerstone of our service. We achieve this through meticulous project planning, regular progress monitoring, and proactive communication. Our experienced project managers work diligently to anticipate and mitigate any delays, ensuring your project stays on schedule.

Contact Us

Get Started With Rich Mold Now!

We always want to make sure that our customers are getting the best deal, so let us know what you’re interested in and we’ll get back with a quote!